Let op! Vrijdag 18 april worden er geen bestellingen verzonden.

Phantom spantangen ER volgens DIN 6499 B / ISO 15488 B

Phantom ER spantangen zijn uit- en inwendig geslepen en ultrafijn nabewerkt waarbij een ruwheid < Rz 2,5 wordt gerealiseerd. Phantom spantangen hebben een groot spanbereik tot wel -1 mm en hardheid van HRc 45+2.

Phantom kan de volgende spantangen leveren voor diverse toepassingen.

ER Standaard spantang

Rondloopnauwkeurigheid < 0,015 mm

De standaard spantang wordt gebruikt voor gereedschappen met ronde schacht.

ER Ultra precisie spantang

Rondloopnauwkeurigheid < 0,005 mm

Deze spantang wordt gebruikt wanneer er hoge precisie vereist is, denk hierbij aan gebruik VHM gereedschappen, boor- en freesbewerkingen en ruimen.

ER Rubberafgedichte precisie spantang

Rondloopnauwkeurigheid < 0,008 mm

Afdichting tot max. 40 bar

De spantang wordt gebruikt voor gereedschappen met ronde schacht met interne koeling. Door het geringere spanbereik dient de boring van de spantang overeen te komen met de schachtdiameter van het gereedschap.

ER Mechanisch afgedichte precisie spantang

Rondloopnauwkeurigheid < 0,008 mm

Afdichting tot max. 120 bar

De spantang gebruikt voor gereedschappen met ronde schacht met interne koeling en waarbij een hogere druk dan 40 bar wordt toegepast, bijvoorbeeld kanonboren.

Door het geringere spanbereik dient de boring van de spantang overeen te komen met de schachtdiameter van het gereedschap.

ER Rubberafgedichte ”coolant jet precisie” spantang

Rondloopnauwkeurigheid < 0,008 mm

Afdichting tot max. 40 bar

Spantang met extra koelkanalen in de spantang voor gebruik van gereedschap zonder interne koeling.

Door het geringere spanbereik dient de boring van de spantang overeen te komen met de schachtdiameter van het gereedschap.

ER Tapspantang

Rondloopnauwkeurigheid < 0,008 mm

Spantang voor het gebruik van tappen. Met meeneemvierkant voor de tap tegen verdraaing in de spantang.

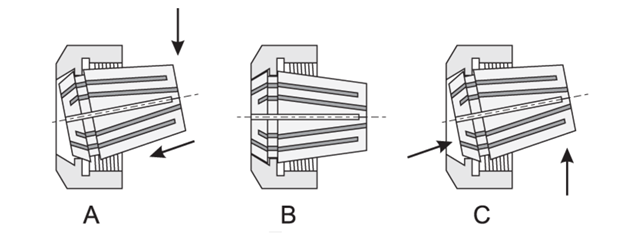

A- Plaats de spantang in de spantangmoer, draai totdat de excentrische ring in de groef van de spantang valt. Druk dan de spantang in de richting van de pijlen tot hij in de moer klikt.

B- Plaats spantang en spantangmoer samen in de spantanghouder.

Hierna kan het gereedschap, nadat de schacht is schoongemaakt, in de spantang worden geplaatst en de moer worden aangedraaid.

C- Om het gereedschap te demonteren draai je de moer met een sleutel los en door de excentrische ring wordt de spantang uit de spantanghouder getrokken. Verwijder het gereedschap uit de spantang en draai de moer met spantang volledig van de houder.

De spantang kan door in de richting van de pijlen te drukken uit de moer worden verwijderd.