Guide de la sélection de fraises limes

Une fraise lime se compose tout d’abord d’une tête de coupe en carbure munie de tranchants reliée à une queue en acier. La fraise lime rotative est utilisée pour enlever des copeaux manuellement sur diverses matières, le ponçage de pièces ou l'usinage de soudures.

Modèles de fraises limes

Il existe un modèle ou une forme de fraise lime pour presque chaque type d'usinage. Ces formes de fraises limes sont également indiquées par des lettres de l'alphabet. Les modèles de fraises limes les plus fréquents sont :

Le choix de la fraise lime dépendra de la pièce à travailler et du type de matériel à usiner. Pour les matériaux dont l'usinage est difficile ou pour prolonger la durée de vie des fraises limes, nous avons également des fraises en version revêtues.

Fraise lime ou coffret de fraises lime ?

Les fraises limes sont disponible en queue de 3, 6 ou 8 mm. (la taille de tige la plus courante est 6 mm.) Les fraises lime peuvent être obtenues séparément ou en coffret. Un coffret de serrurier spécial, avec des fraises spécifiques, est spécialement conçu pour ouvrir facilement.

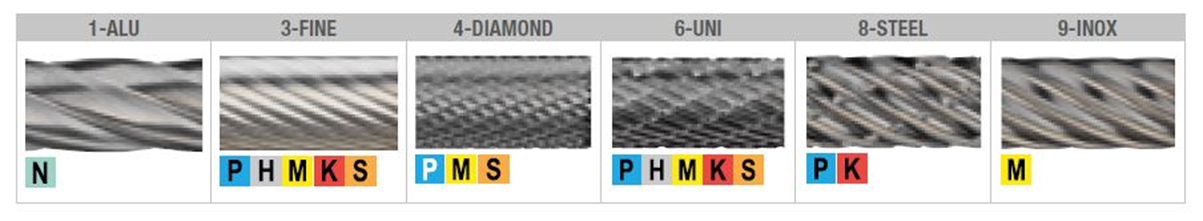

Type de dentures des fraises lime

Le choix de la forme de la denture dépend du matière à usiner. Nous proposons les formes suivantes à la gamme :

- Type de denture 1-ALU : adaptée aux aluminiums et aux matériaux synthétiques, fraise avec une coupe rugueuse pour une évacuation optimale des copeaux

- Type de denture 3-FINE : fraise lime pour les matériaux durs et/ou résistants et les inox, pourvue d'une fine denture pour une bonne finition et une utilisation universelle

- Type de denture 4-DIAMOND : fraise lime pourvue d'une denture en diamant pour l'ébavurage fin et la finition de l'acier, l'acier trempé, les matériaux composites et les matériaux résistant à la chaleur (nickel/cobalt)

- Type de denture 6-UNI : fraise lime pourvue d'une denture universelle pour les matériaux et les usinages les plus courants. Elle produit des copeaux courts

- Type de denture 8-STEEL : fraise lime pour une élimination élevée sur l'acier et la fonte

- Type de denture 9-INOX : Spécialement appropriée pour l'usinage d'acier inoxydable, de matériaux doux et d'alliages légers